I think you are over thinking it.... They don't know the difference between mRNA and Campbell's alphabet soup.

_thebrain_

Underrated comment.

Looks like a banjo fitting. You'll need to know the diameter of the center stud but several companies offer banjo adapters. A good hose shop will be able to make you a replacement hose/fix that hose relatively easy.

I had a green line on my screen. There is a problem with early pixel 8 / 8 pro screens and there is an extended warranty where they will replace it free. I don't even think you need to be the original owner.

https://support.google.com/pixelphone/answer/15009955?hl=en

Mine took about a week after I filled out the paperwork and was approved. I got back my original phone with a new screen on it, same IMEI etc.

Itay not be the opening song or sequence, but the opening scene in the umbrella academy were always amazing when they did a song/dance number. Their soundtrack spanning the whole series were full of bangers... But the best has to be season three episode one, the dance off with the sparrow academy.

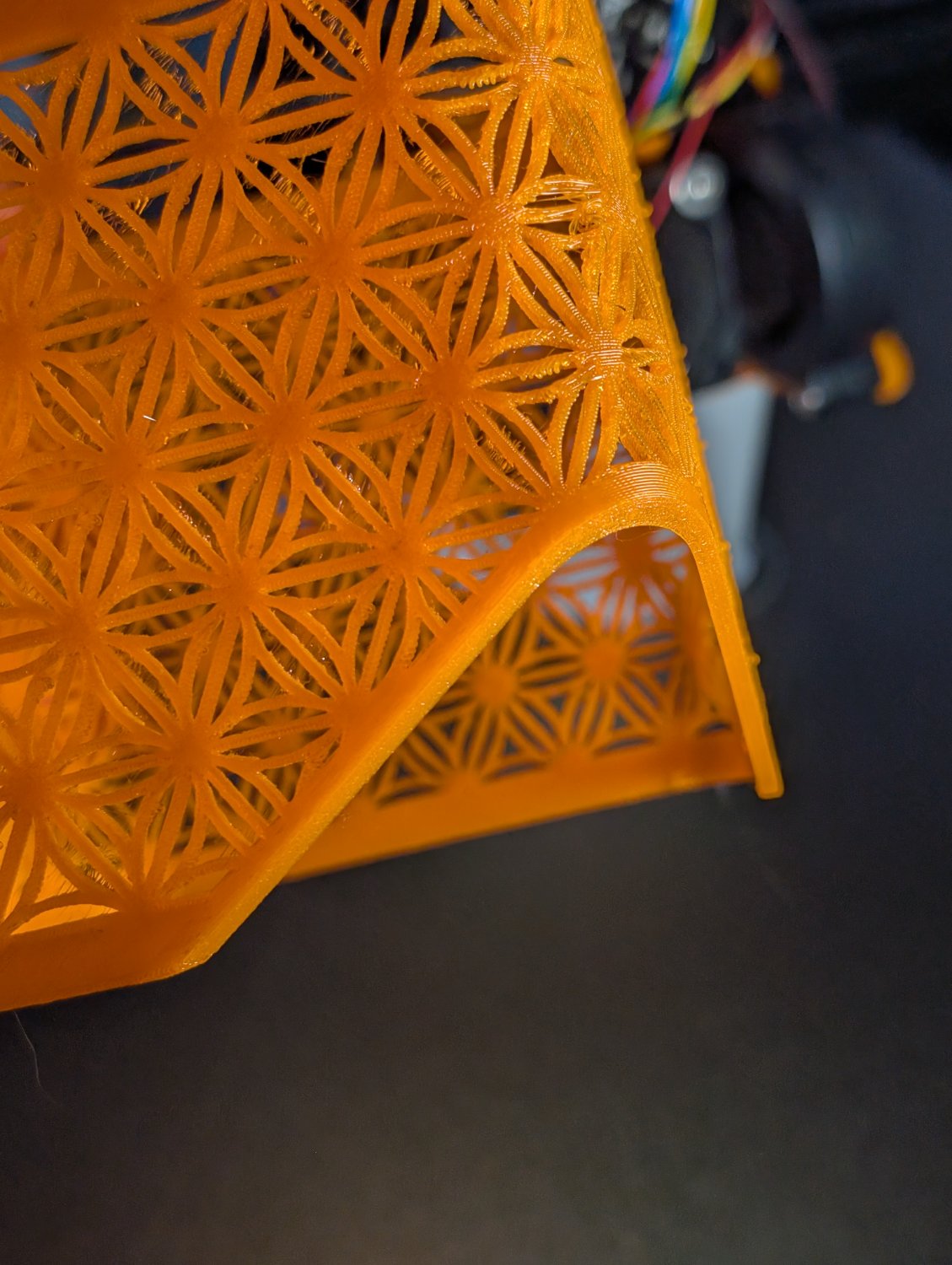

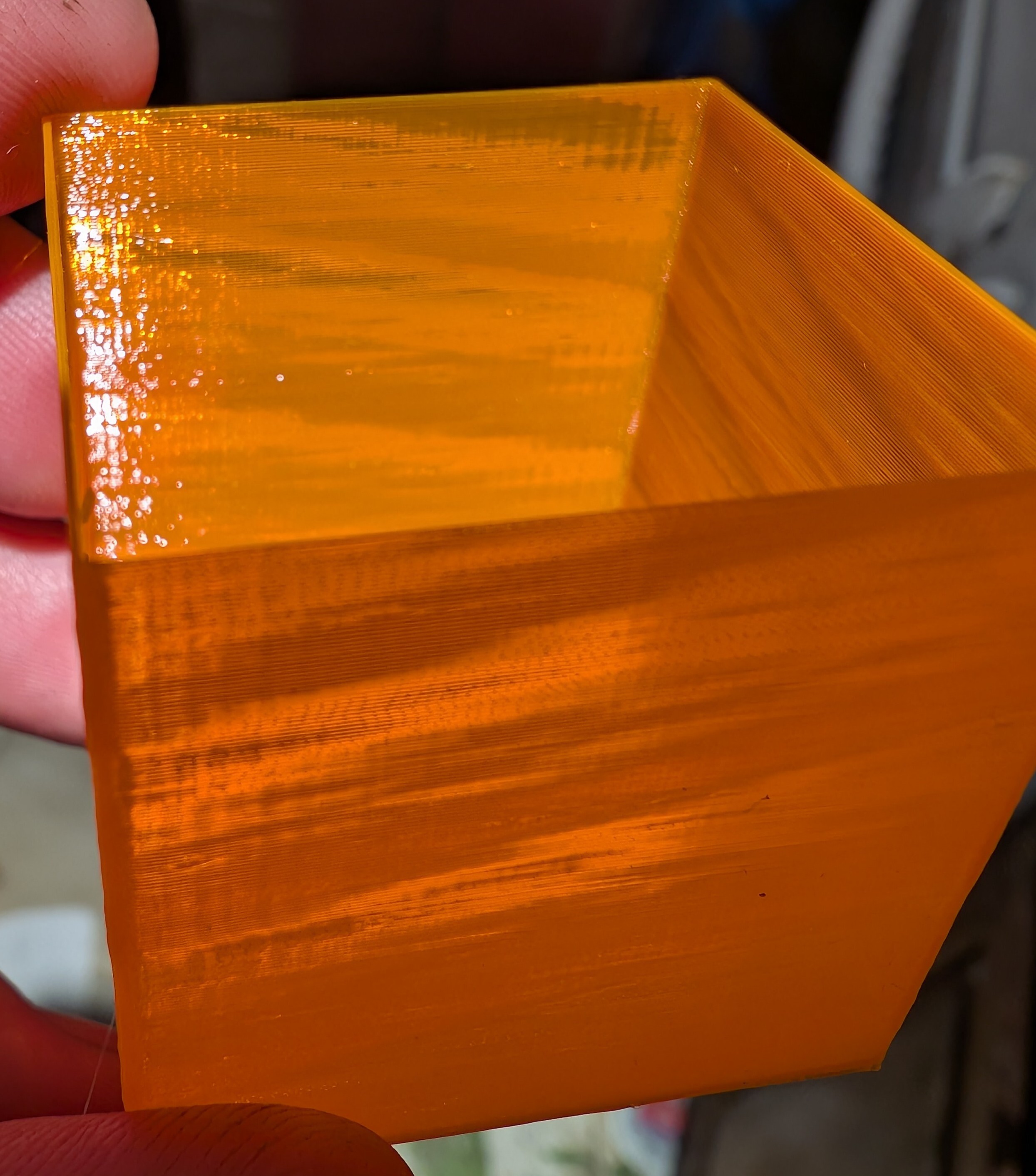

Exactly. I don't know the expected life span of 3m 468mp but apparently I exceeded it in my environment and duty cycle. I'm still working on getting the residue off of the bed however, and I can say that where it stuck, and did not fail, it did an excellent job, even pulling off bits of silicone with the glue.

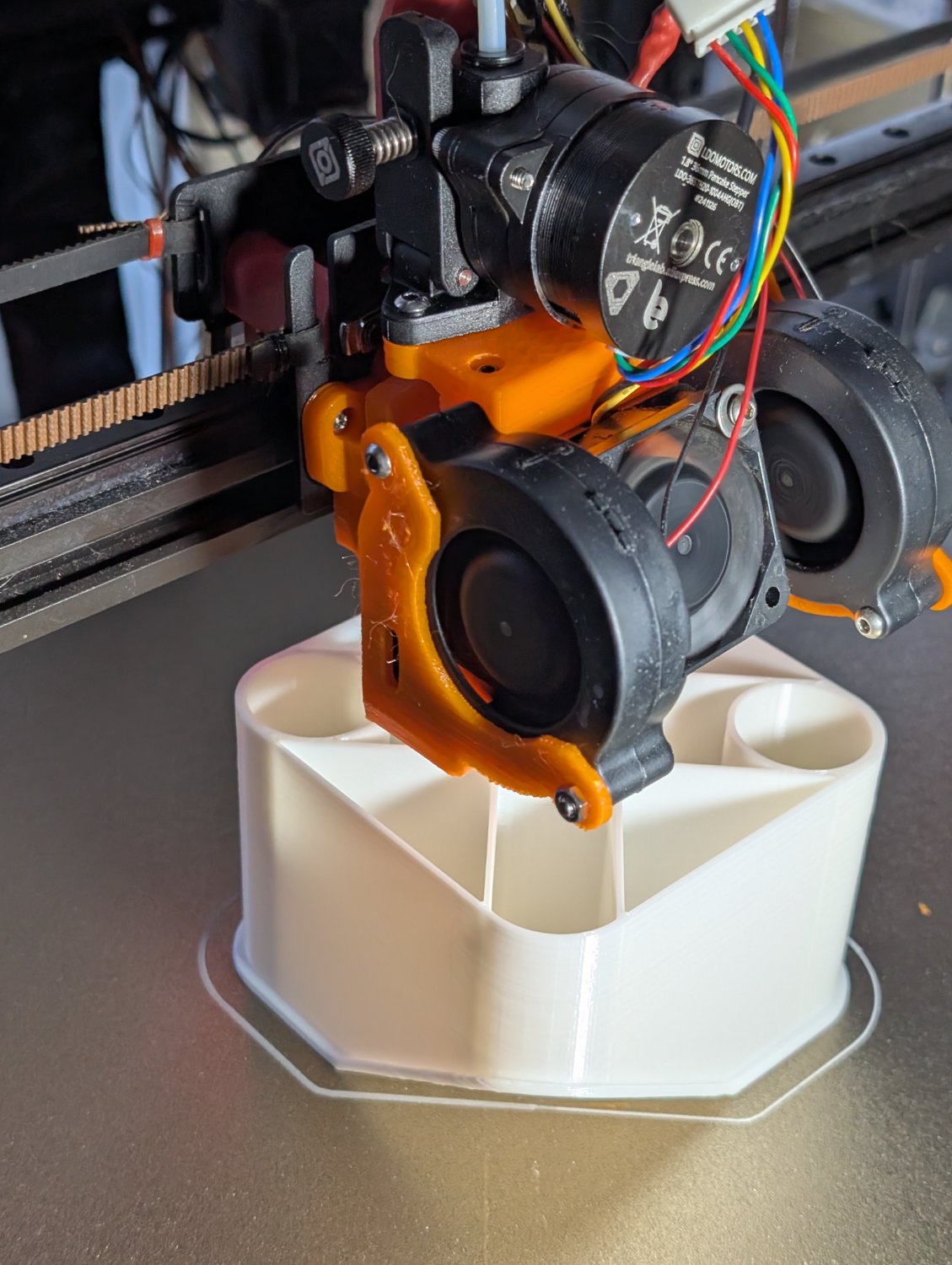

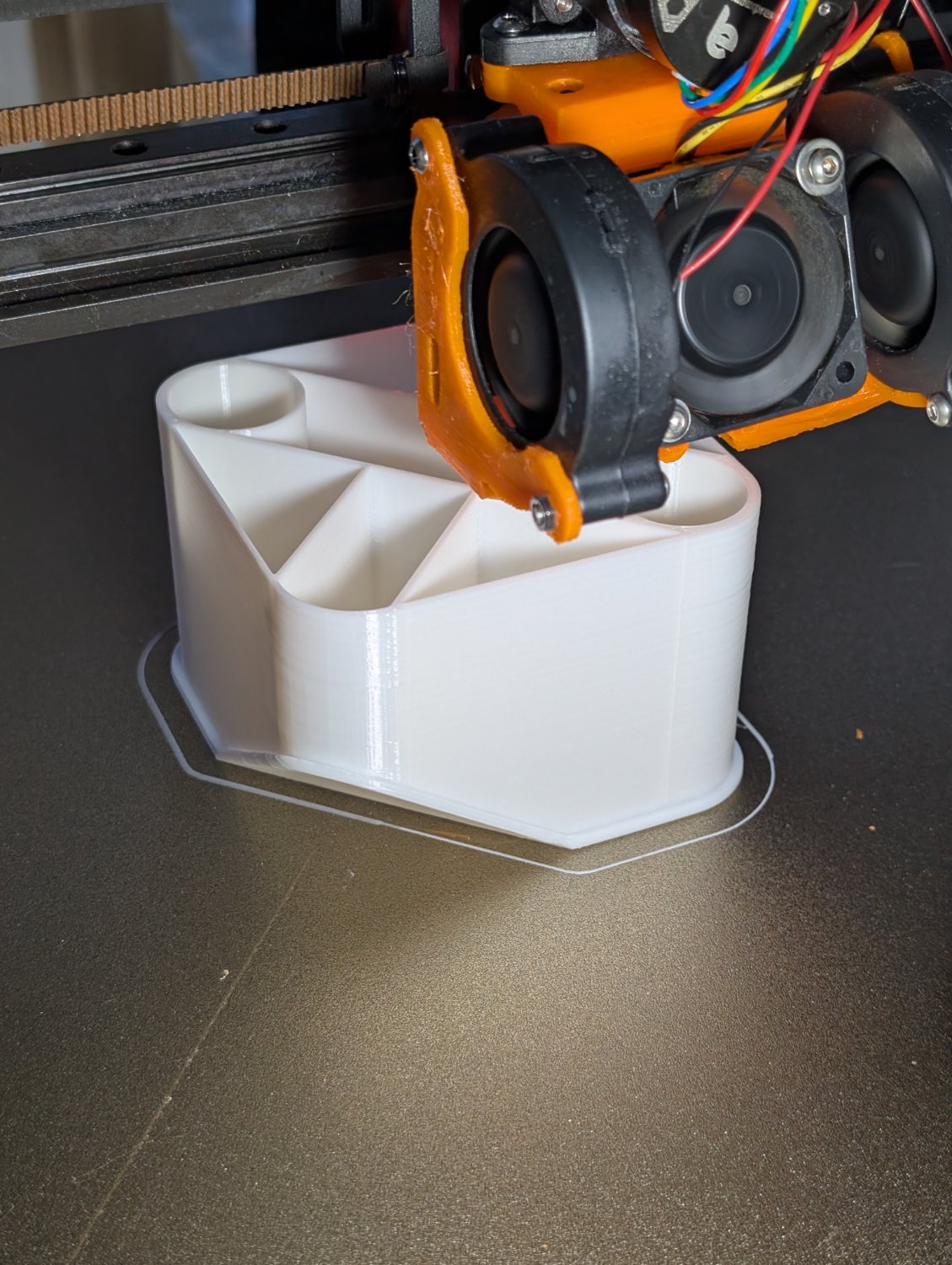

I have had it since probably 2018? It was one of the original x5sa kits. Honestly it has been a good platform to learn off of

Custom. It started life as a tronxy x5sa-400 but I think only 2 steppers and the frame are original still. I changed the bed to a 16"^2^ *3/8 thick aluminum tool plate about 5 years ago. It always worked well for me. Unfortunately the silicone mat I used doesn't seem to be made any more. I'm going to try one meant for a creality cr10 S4. I may have to re-machine the mounting holes for the thru holes on the mat tho.

cd ..

My company uses a VPN where the client is so slow inside the VM it is functionally useless. 99%of the time I can still get away with it because my connection amounts to a couple of telnet sessions, but when I actually need data or a spreadsheet or something transferred local, I need to fire up windows directly to snag it.

Sonicwall has a VPN client that will run fine on Linux (or so they say), but the company won't switch over to it. And sonicwall considers the windows only version eol and won't add a Linux version

I got tired of windows updates breaking my dual boot. After some research I found that it's possible to have two uefi partitions: one for windows and one for Linux. It's not standard but there is nothing expressly written into the efi spec that prohibits it. And it just works. My bios doesn't care, and works with them both just fine.

I only use Windows for that 1% of business stuff I can't accomplish in a vm under windows. Invariably after I boot into widows once ever 3 months it installs so.e update and would kill my ability to boot into Linux. Since setting up 2 partitions I haven't had this problem.

You would think they would start with an easier one like "heil Hitler" being antisemitic, but they seem perfectly okay with that one.