Por que, no los dos?

JakenVeina

No idea. That's the problem. ICE isn't bothering to determine if the people it deports have proper documentation or not. The plethora of incorrectly arrested and/or deported people we DO know about, we only know because journalists and citizens did the investigating. Which is why ICE is working harder and harder to hide any details about what they're doing and who they're arresting.

You know what we, in the industry, call a detailed specification fo requirements detailed enough to produce software? Code.

The REAL problem is that the industry collectively uses JS almost exclusively for shit it was never meant to do. Like you say, it's intended for it to not throw errors and kill your whole web page, because it was only ever intended to be used for minor scripts inside mostly-static HTML and CSS web pages. Then we all turned it into the most-popular language in the world for building GUI applications.

The Supreme Court is about to ~~let~~ use religion to intentionally ruin public education.

Honestly, if you're having trouble finding stuff for vanilla JS, I'd recommend looking at jQuery. Not that you should USE jQuery, necessarily, but the library is basically a giant wrapper around all the native JS APIs, so the approach to building stuff is essentially the same: it all focuses on tracking and manipulation of DOM elements.

I do vanilla JS (actually TypeScript) dev at work, daily, and that was my big takeaway from spearheding our team's migration from jQuery to vanilla TypeScript: I honestly don't know what benefit jQuery provides, over vanilla, because all the most-common jQuery APIs that we were using have a 1:1 native equivalent.

We do also use 2 third-party libraries alongside vanilla, so I'l mention those: require.js and rx.js. Require you probably don't need, with modern JS having bundling and module support built-in but we still use it for legacy reasons. But rx.js is a huge recommend, for me. Reactive programming is the IDEAL way to build GUIs, in my opinion.

Blue Prince sure feels like it counts, our whole family is hooked, and has been playing it every day for about 2 weeks now. Even well after rolling credits.

In a similar vein, I'd have to say Hollow Knight and Outer Wilds. Together with Blue Prince, they all have a storytelling strategy of "you have to put some effort into getting the story out of it", but the effort makes every new discovery or revelation feel super rewarding.

Celeste is the one that comes to mind for a more traditional story that REALLY hit.

Persona 5 comes to mind, too. I was ENGROSSED in that story for months. Even if it went off the rails a couple times.

I'm also gonna shout-out Tales of Symphonia. That game was formative for me.

My wife enjoys it. /shrug

Oof, this speaks to me. I hang up on marketing calls 3-4 times a week, and boy this does sound way more satisfying than just tapping a touchscreen.

If you've only ever been exposed to the depiction of non-verbal, extremely sensitive-to-stimuli, routine-oriented, potentially-violent, autistic kids, that you see on TV, you could be forgiven for thinking this.

But, no, that's only an exceptionally small window of what autism is. Most cases of autism aren't so severe, and most people learn coping strategies as they grow up that let them live relatively-normal lives. Even severe cases can do this, but it tends to take more time, and more focused, expert care.

You probably know autistic adults, and aren't even aware. Or, potentially, you just write them off as being loners or not good with people or having some other character flaw, that ultimately stems from their coping mechanisms.

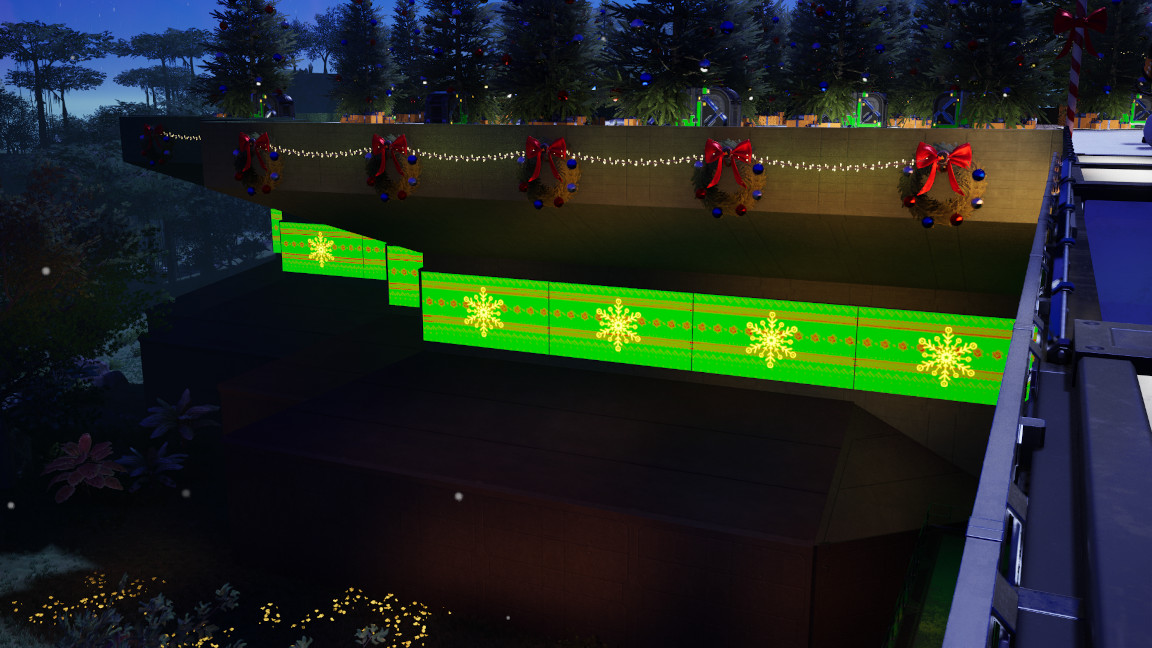

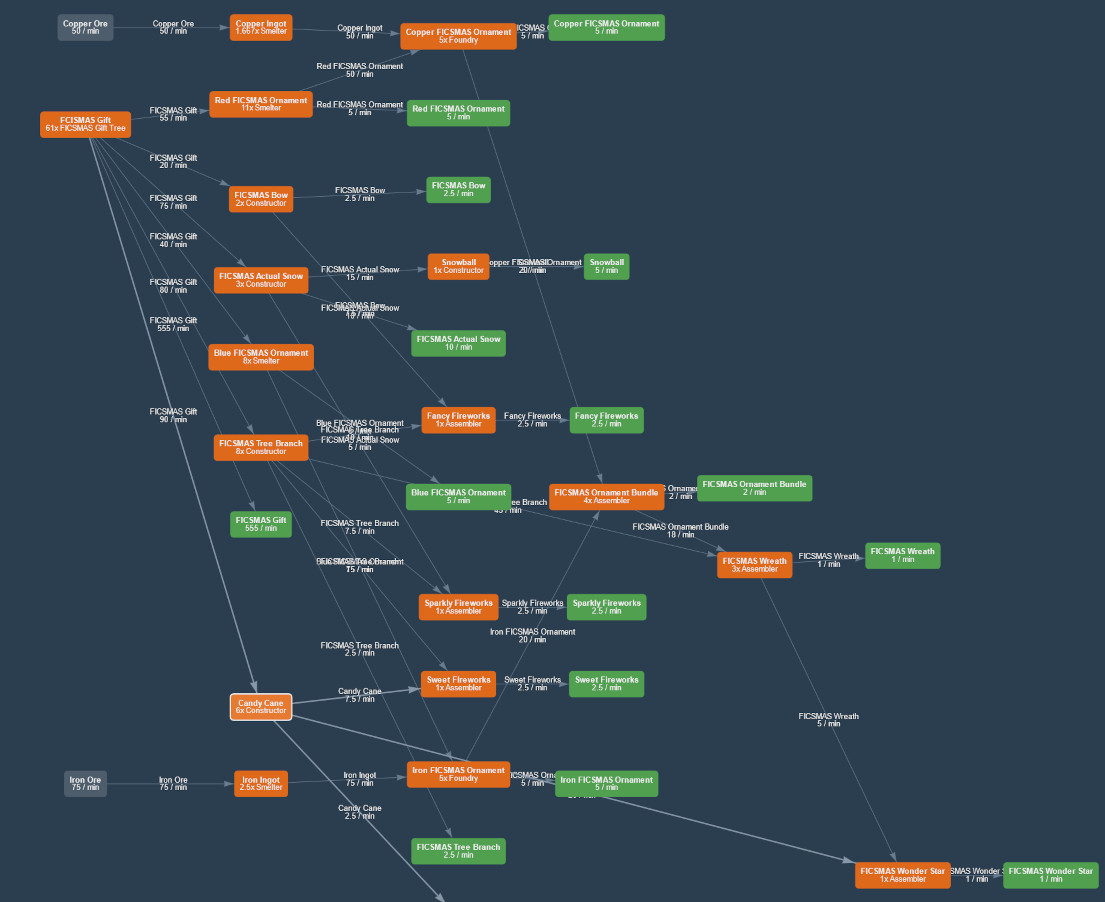

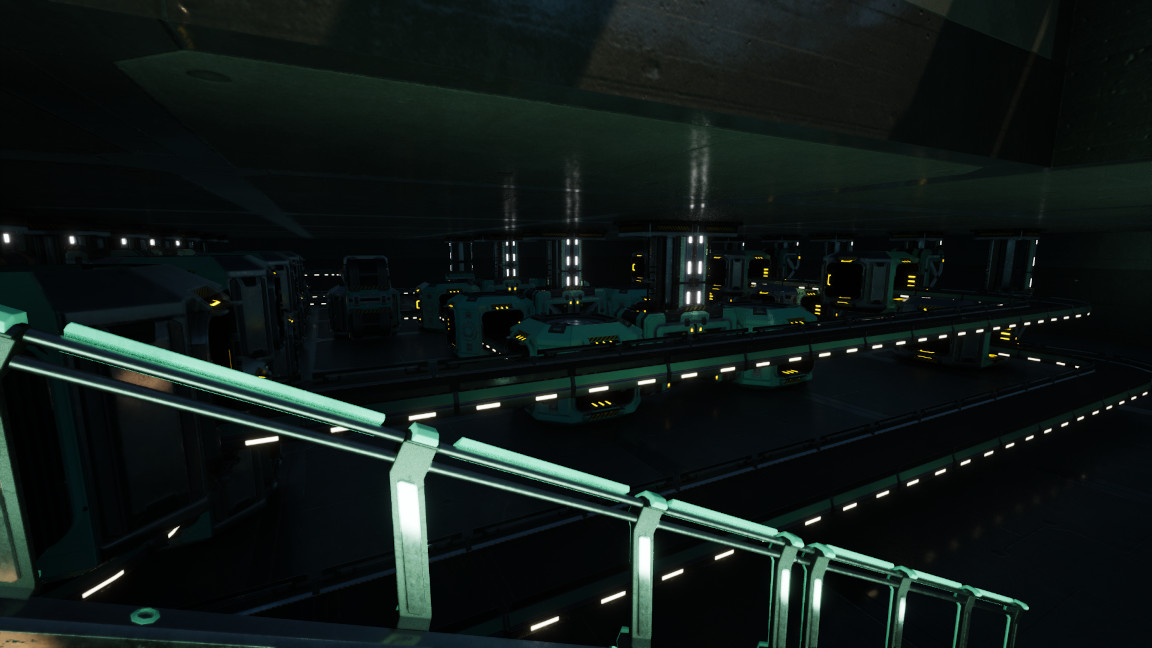

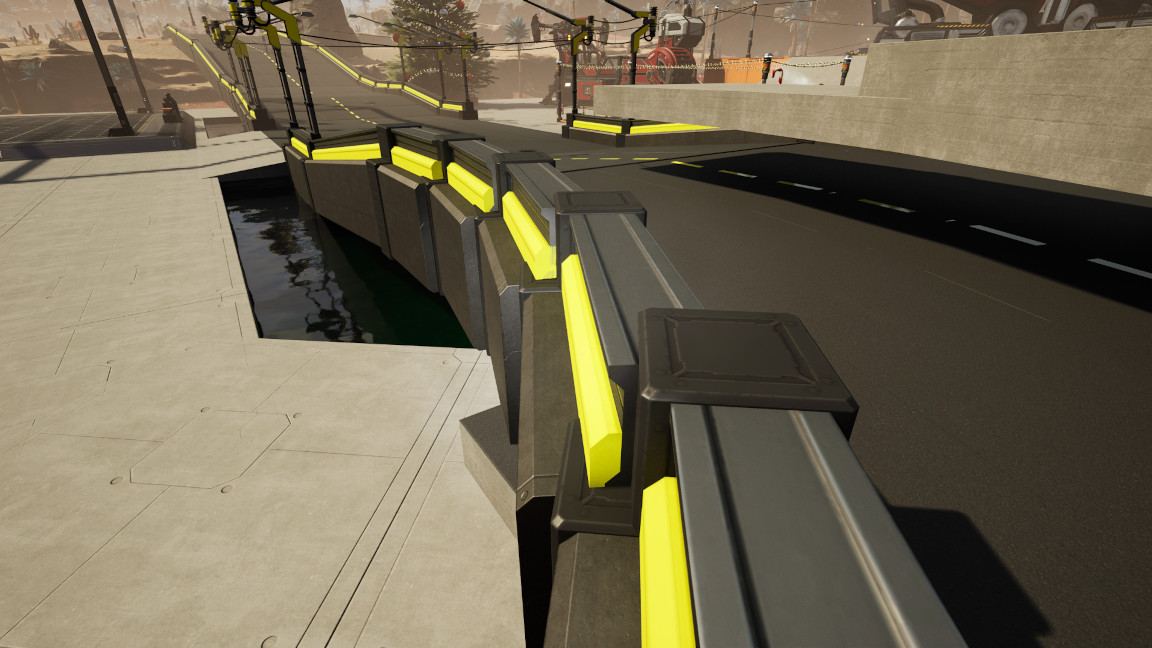

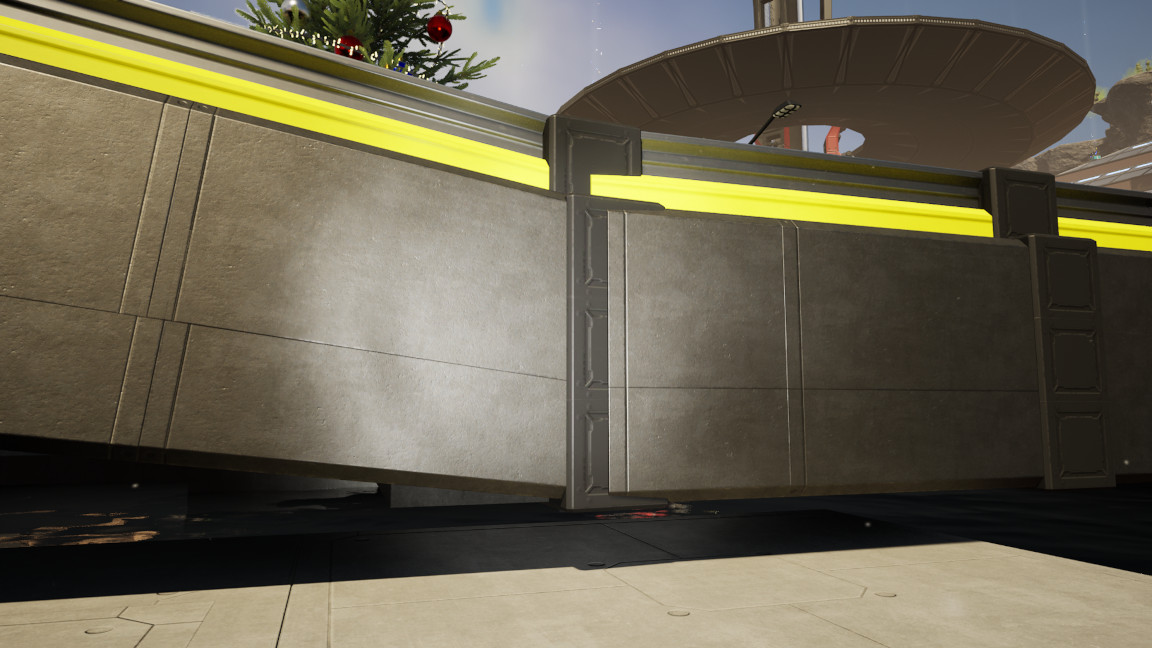

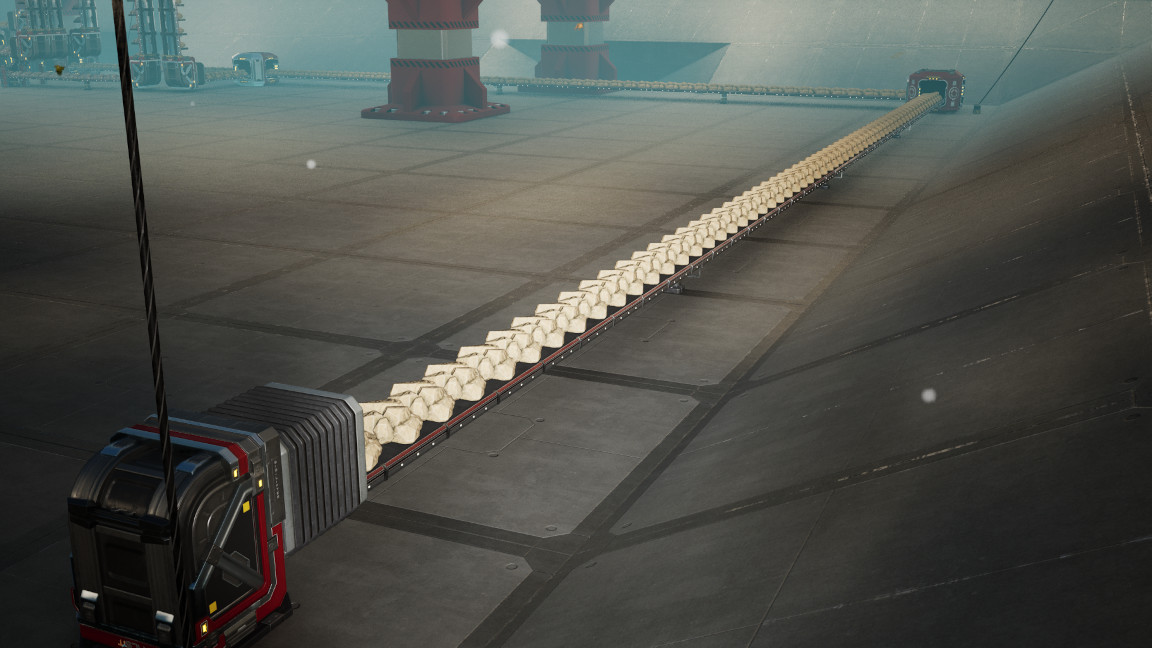

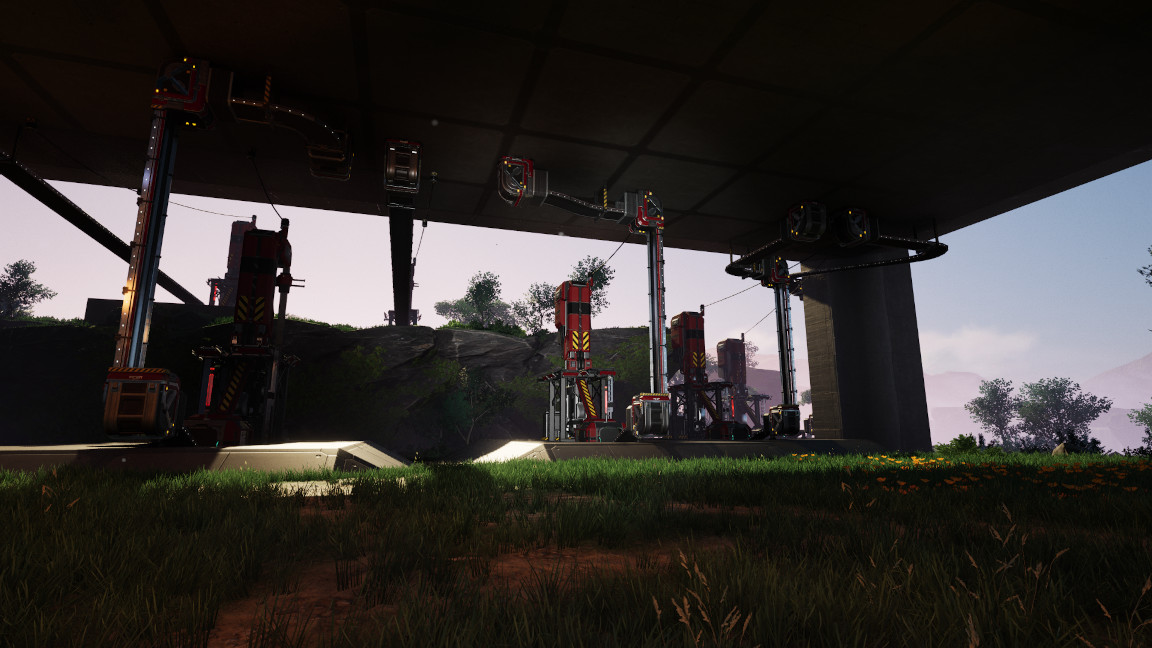

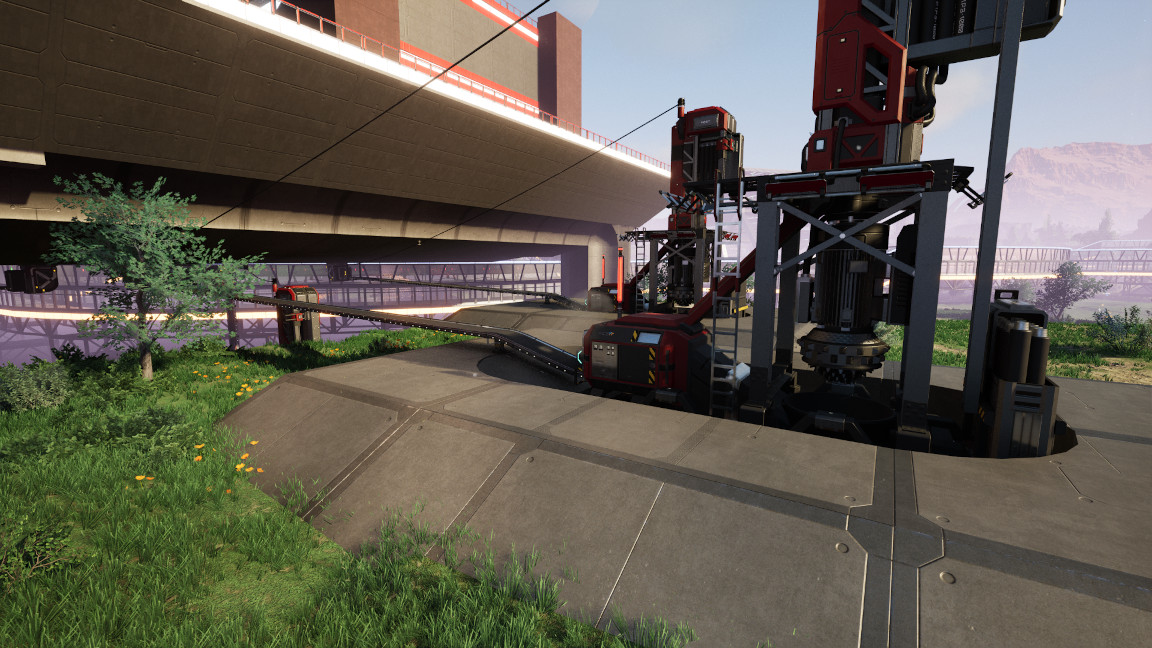

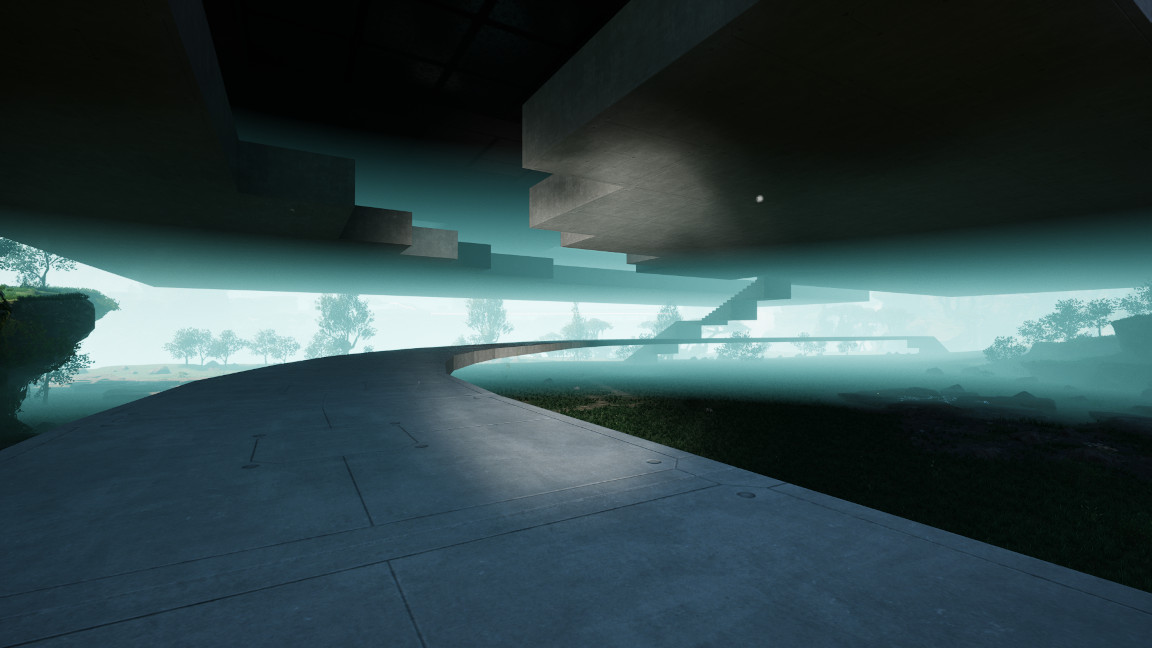

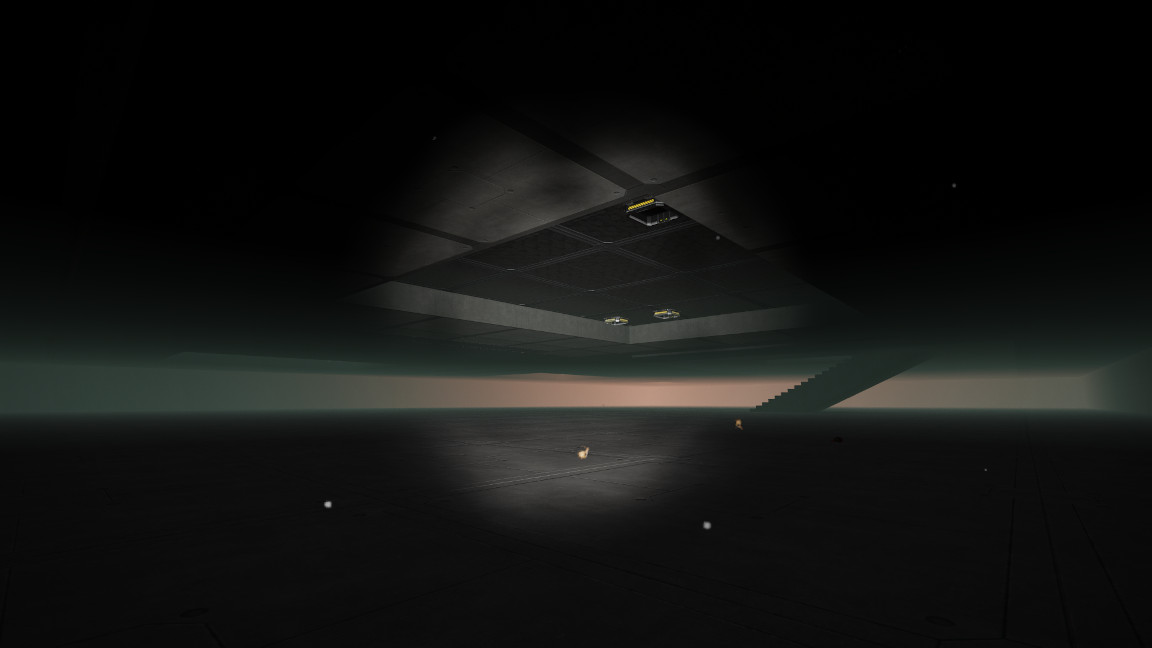

Love it. This is the kinda thing I might wanna try some day, a playthrough where everything is modular and blueprinted, but still looks quite nice.

Ethnic cleansing could turbocharge ethnic cleansing? I mean, I guess, but that's a really weird way to put it.