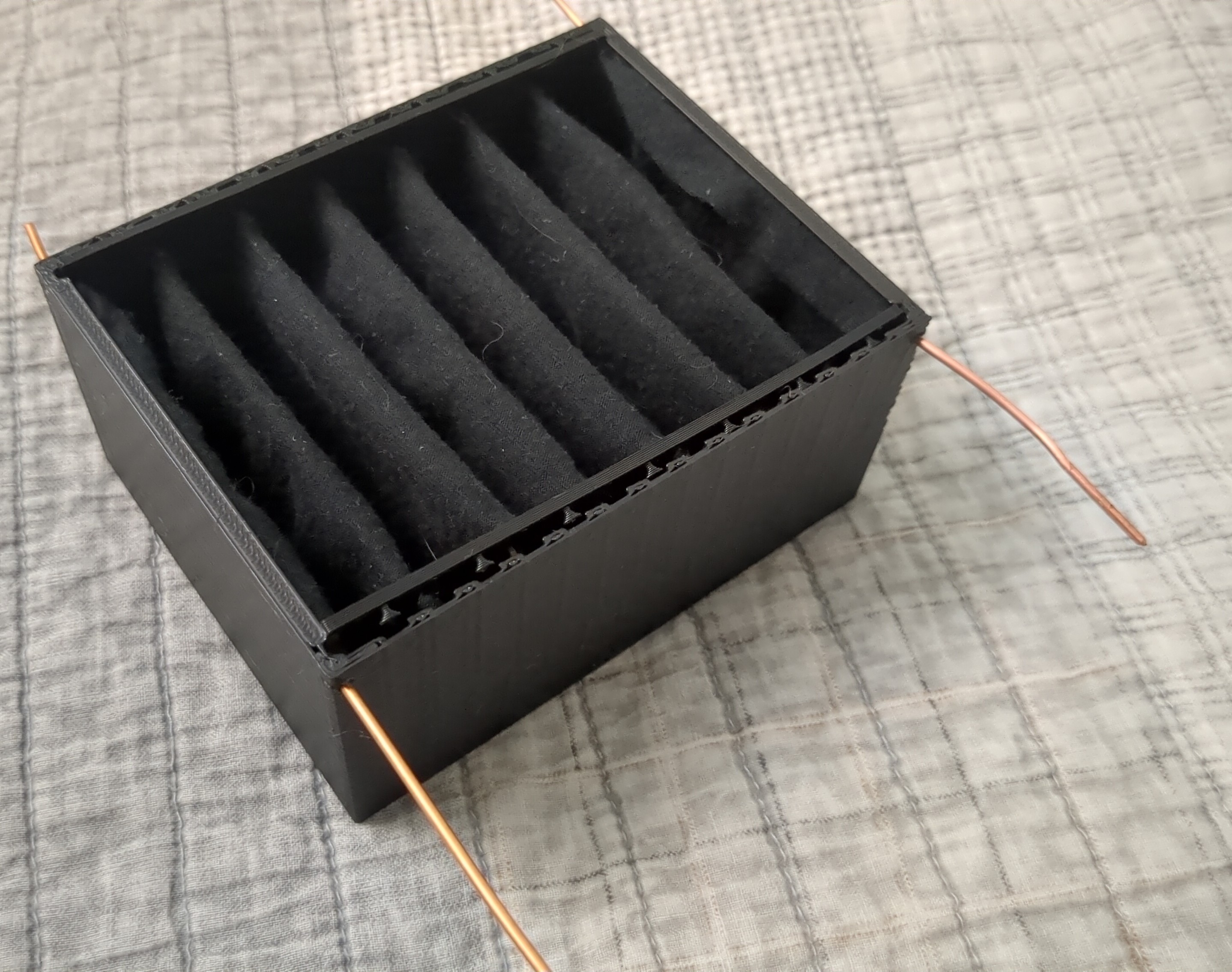

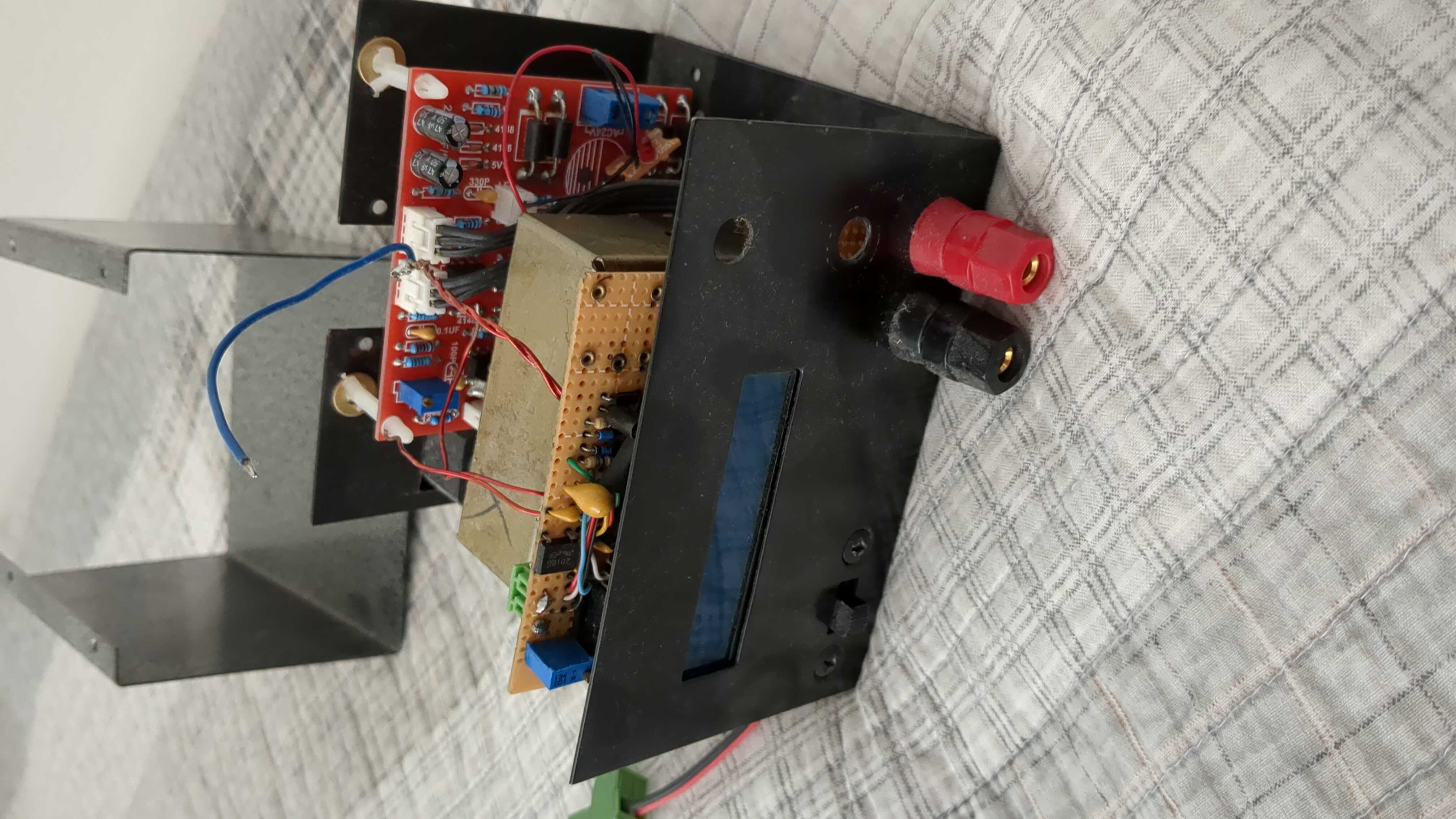

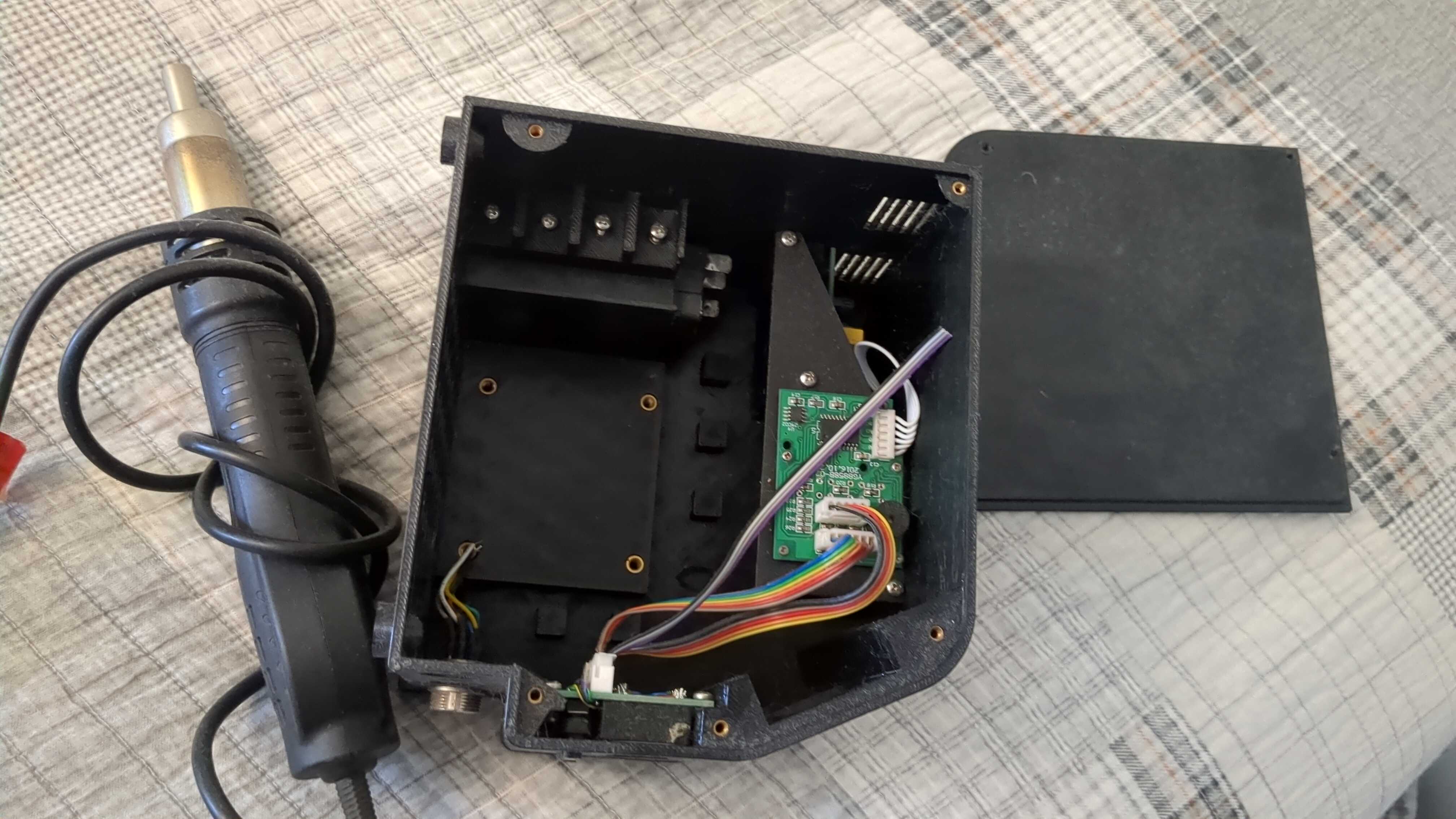

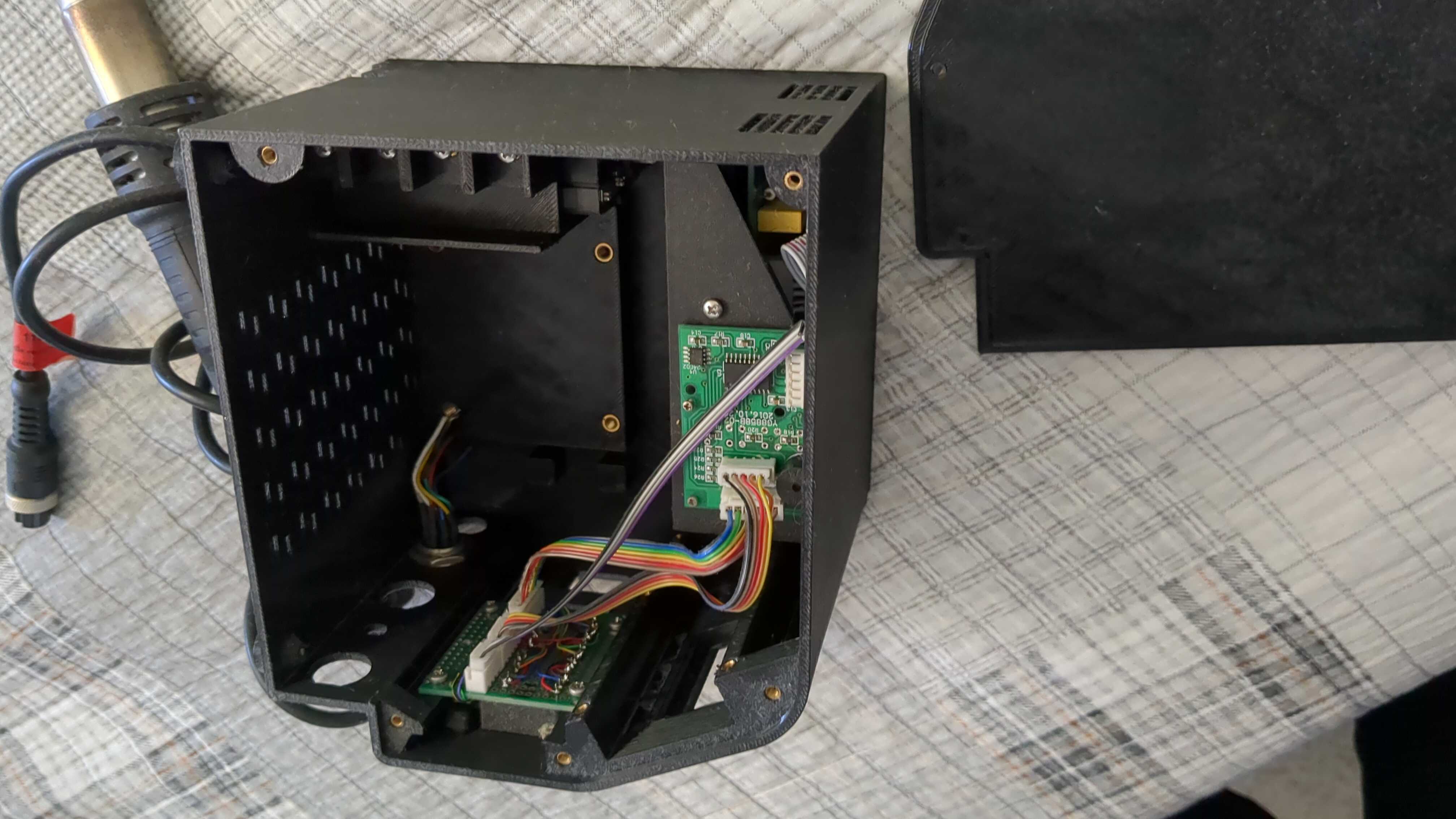

So I just designed and printed the little black enclosure (foreground) with USB and 1/4in jack inserted.

I have a half dozen old Bluetooth headphones that all broke from use over the years. Most are retired from broken wires, but one failed from flexing something loose, and another has a bad batman charge controller.

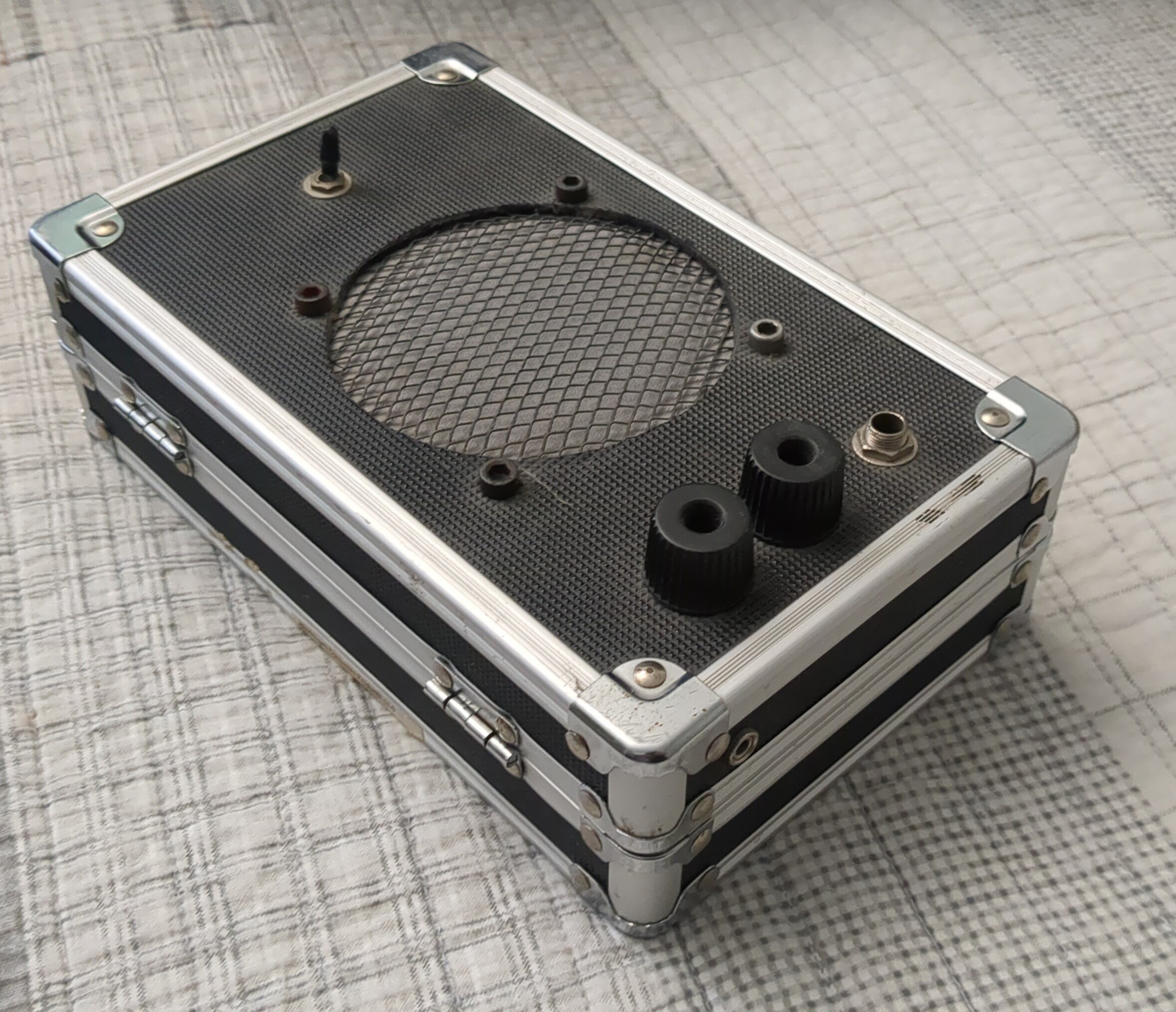

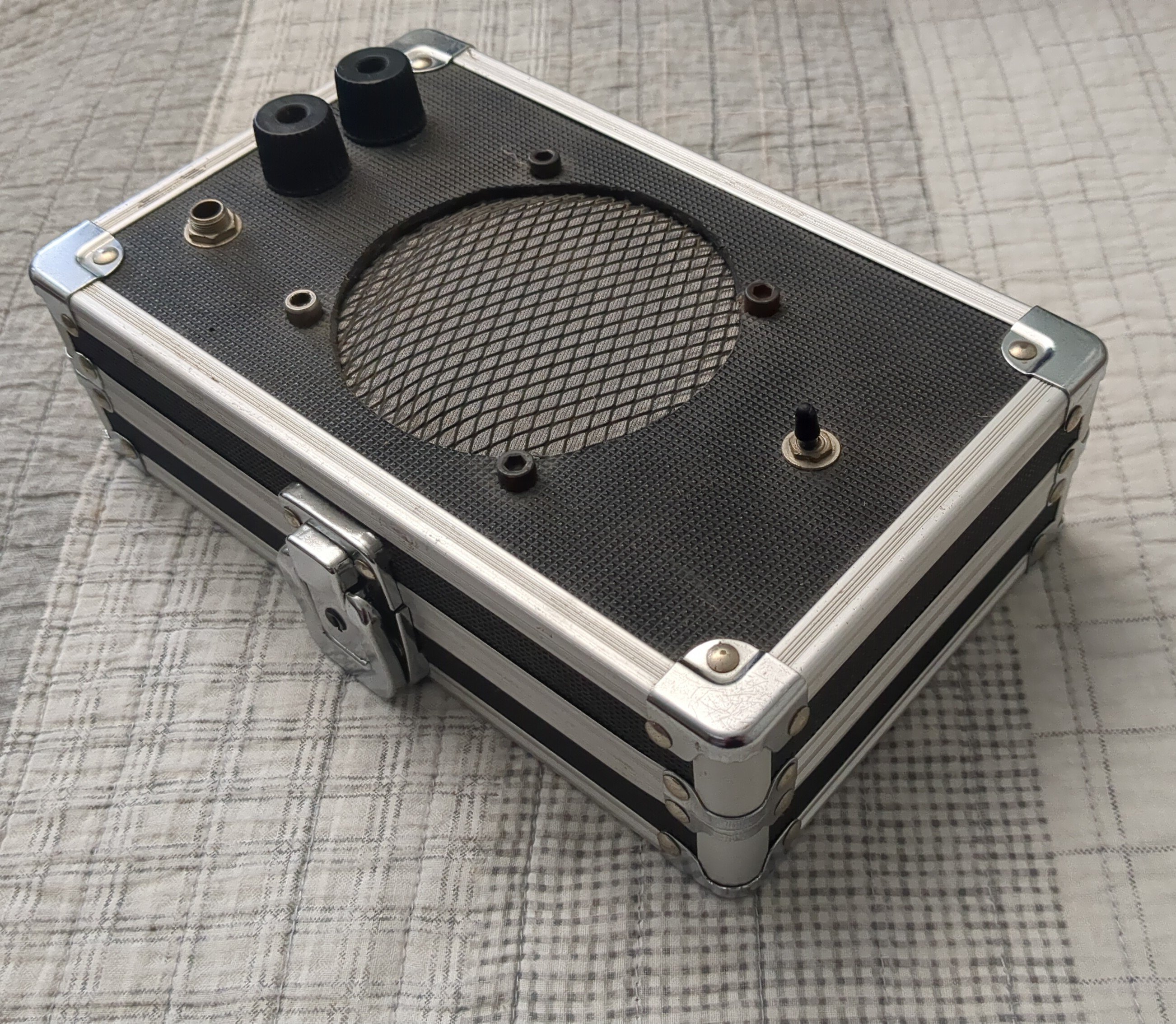

This one I designed the enclosure for is likely going to be a stand alone Bluetooth line-out to a stereo headphone jack with a battery.

I was debating taking out a Bluetooth module from one of my other designs, but then I realized I have a bunch of these headphones, so why not use them.

Today I played around a bit with some of the broken ones trying to figure out what they might do if I hook up a DC source to the battery connection and try to use them. So far the ones I tested were even 5v tolerant for 5-10 minutes at a time. That may make an interesting way to add a Bluetooth line-input into any stereo.

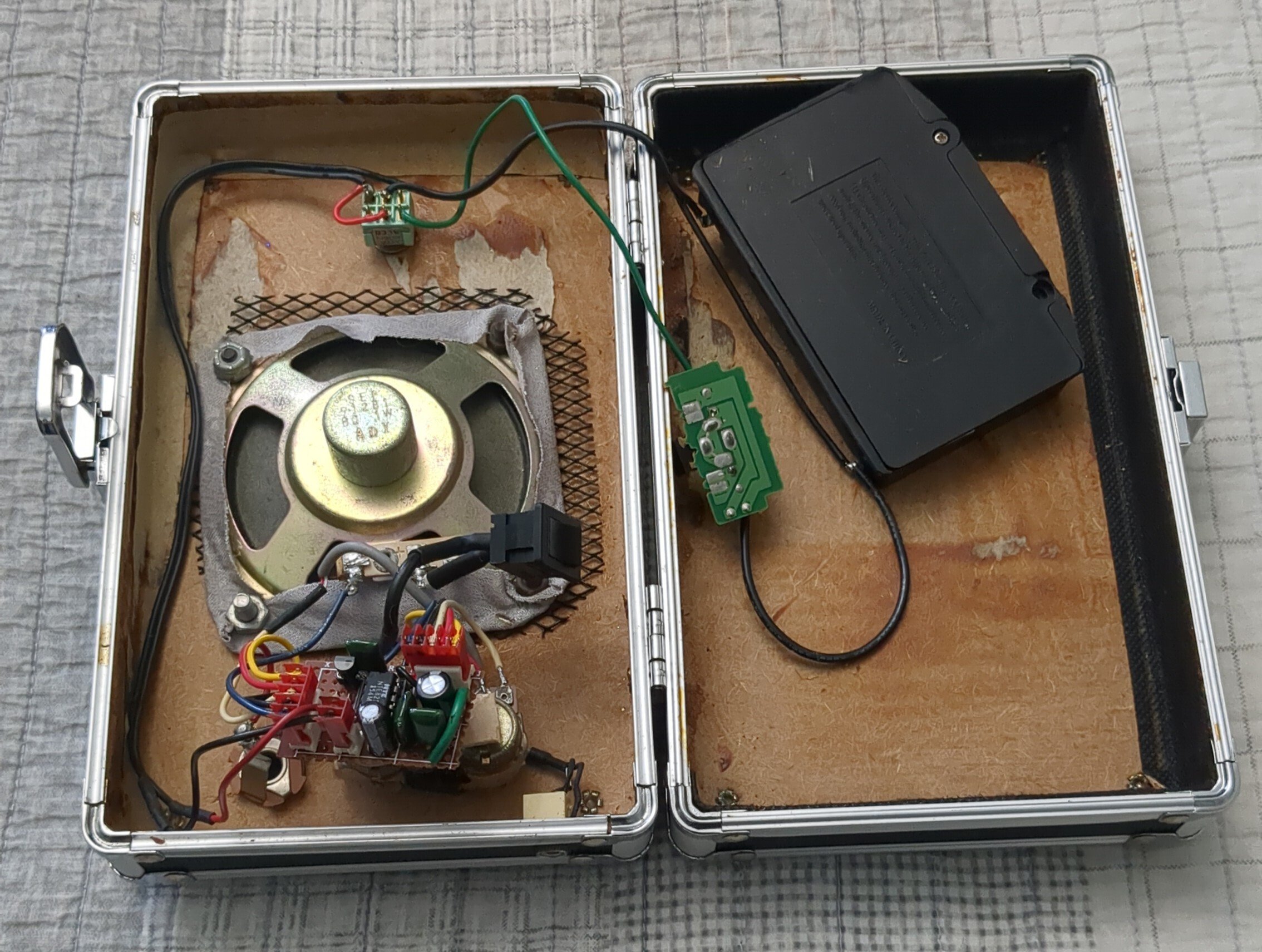

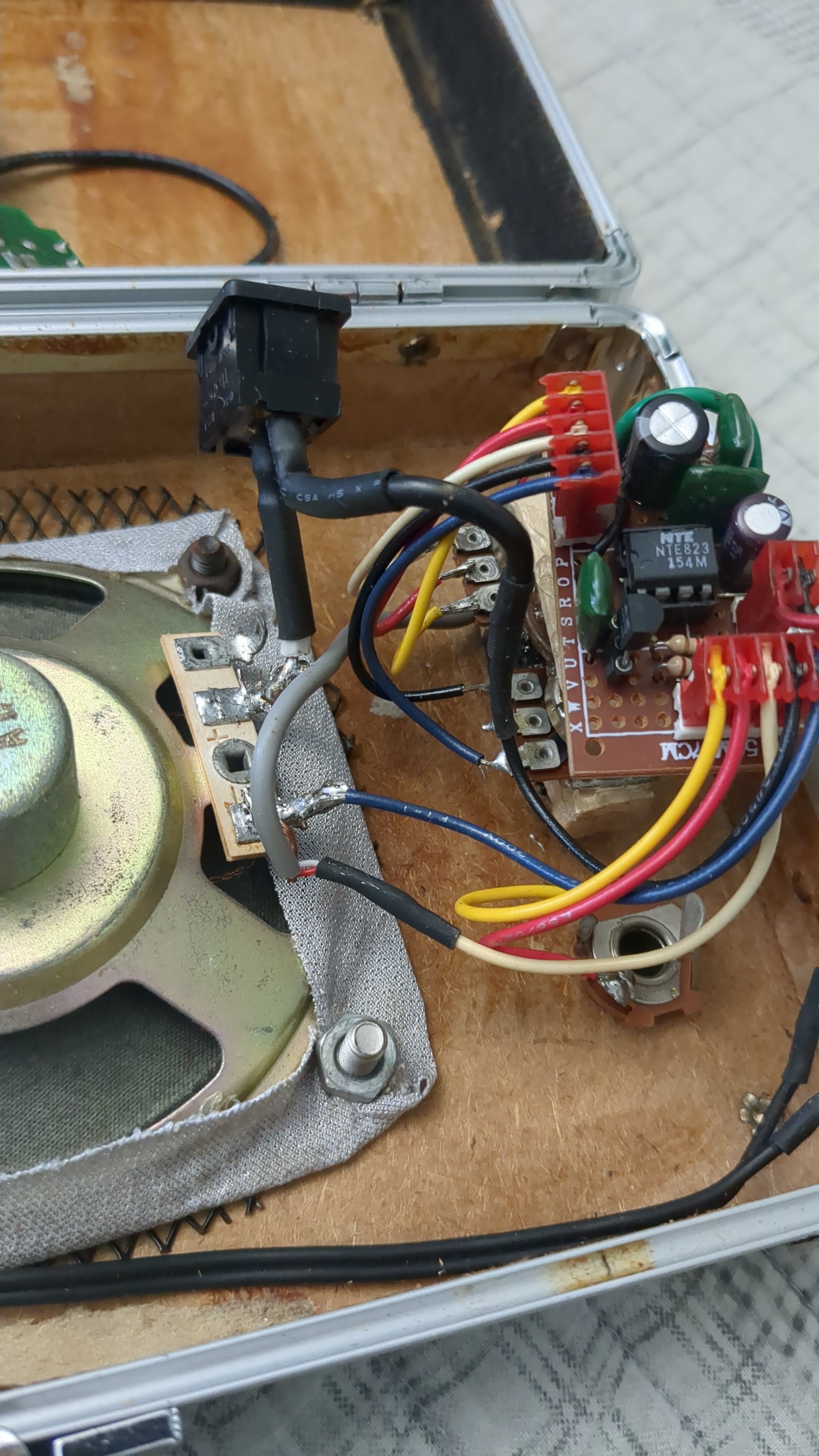

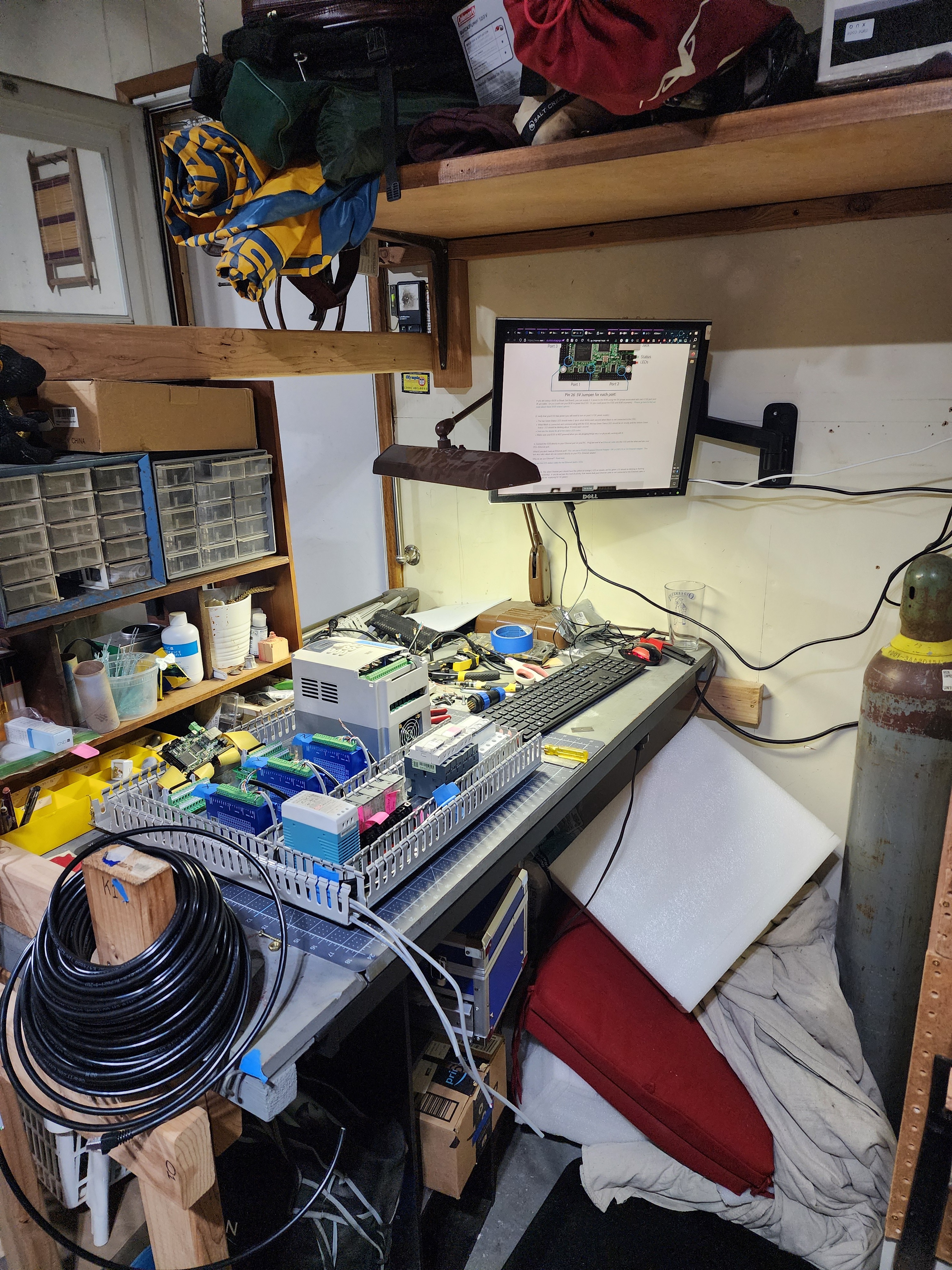

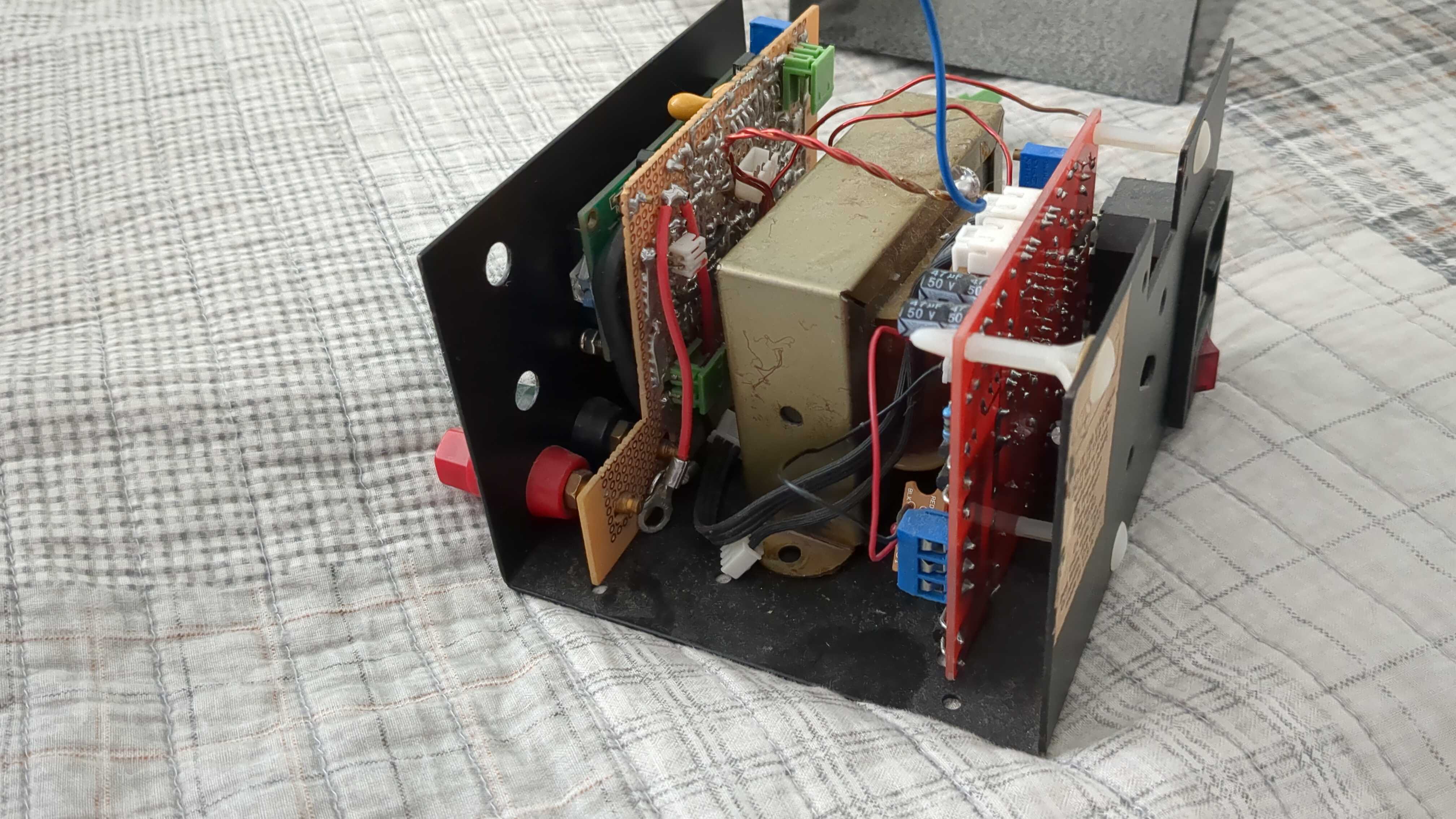

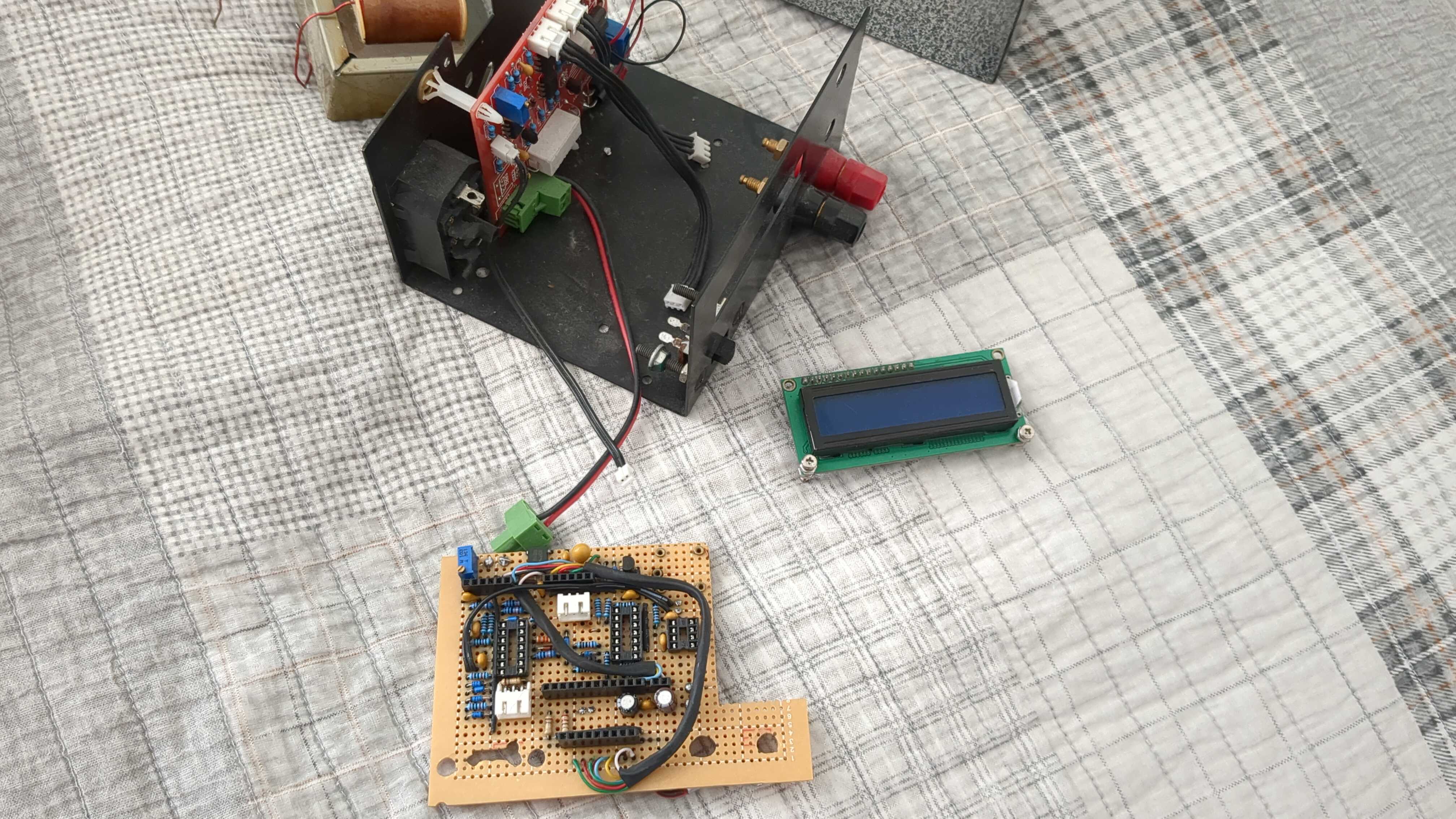

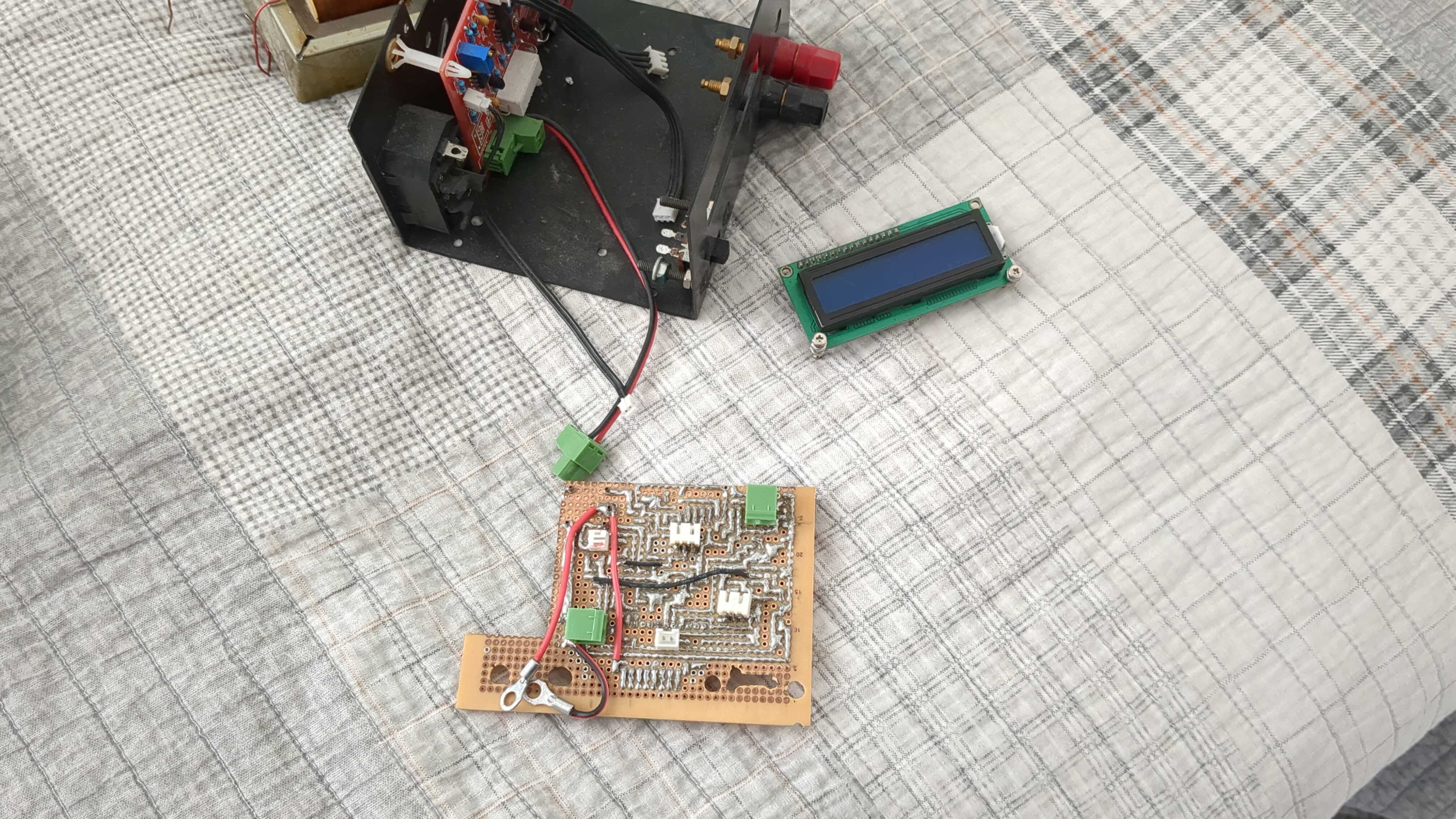

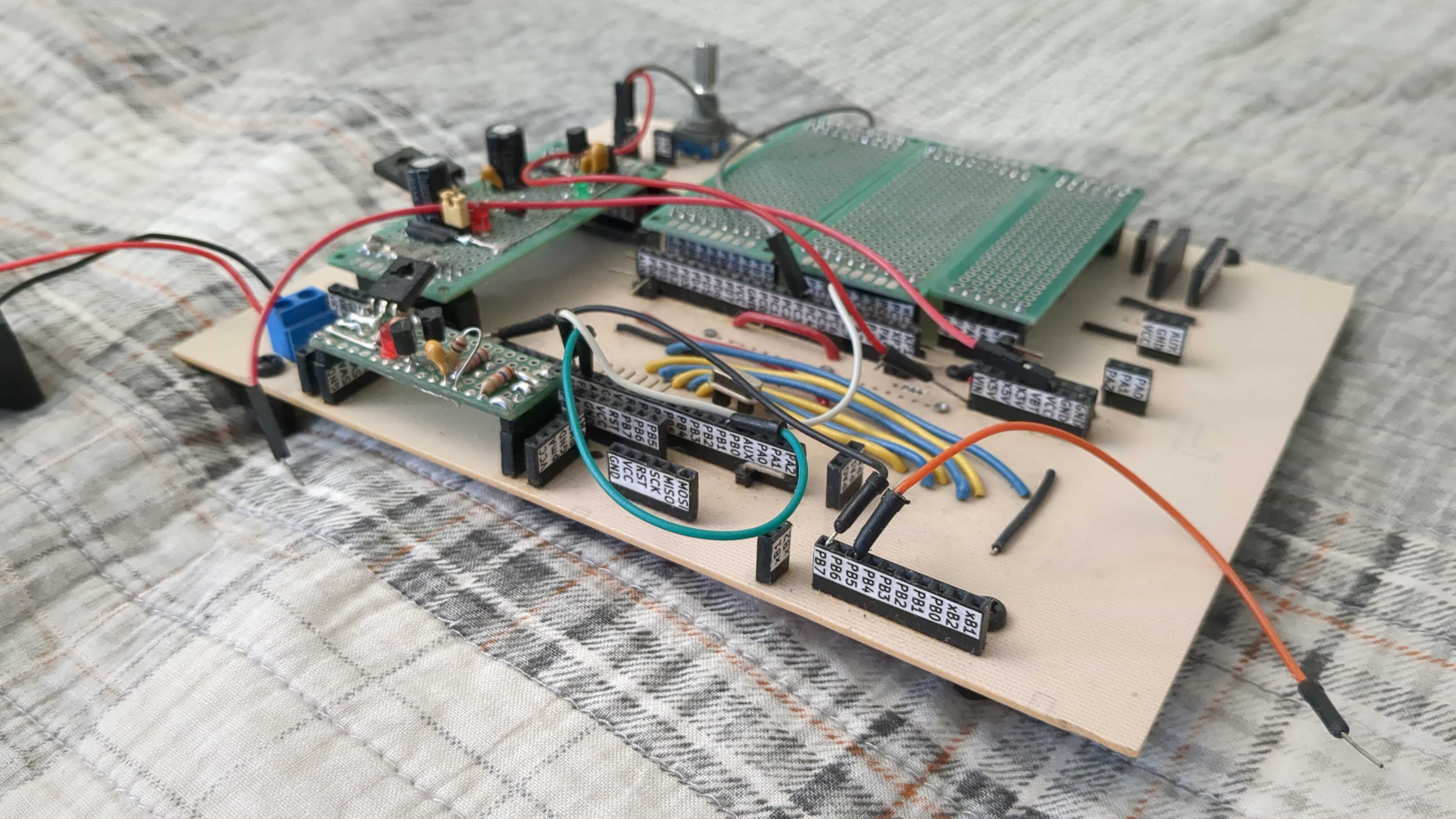

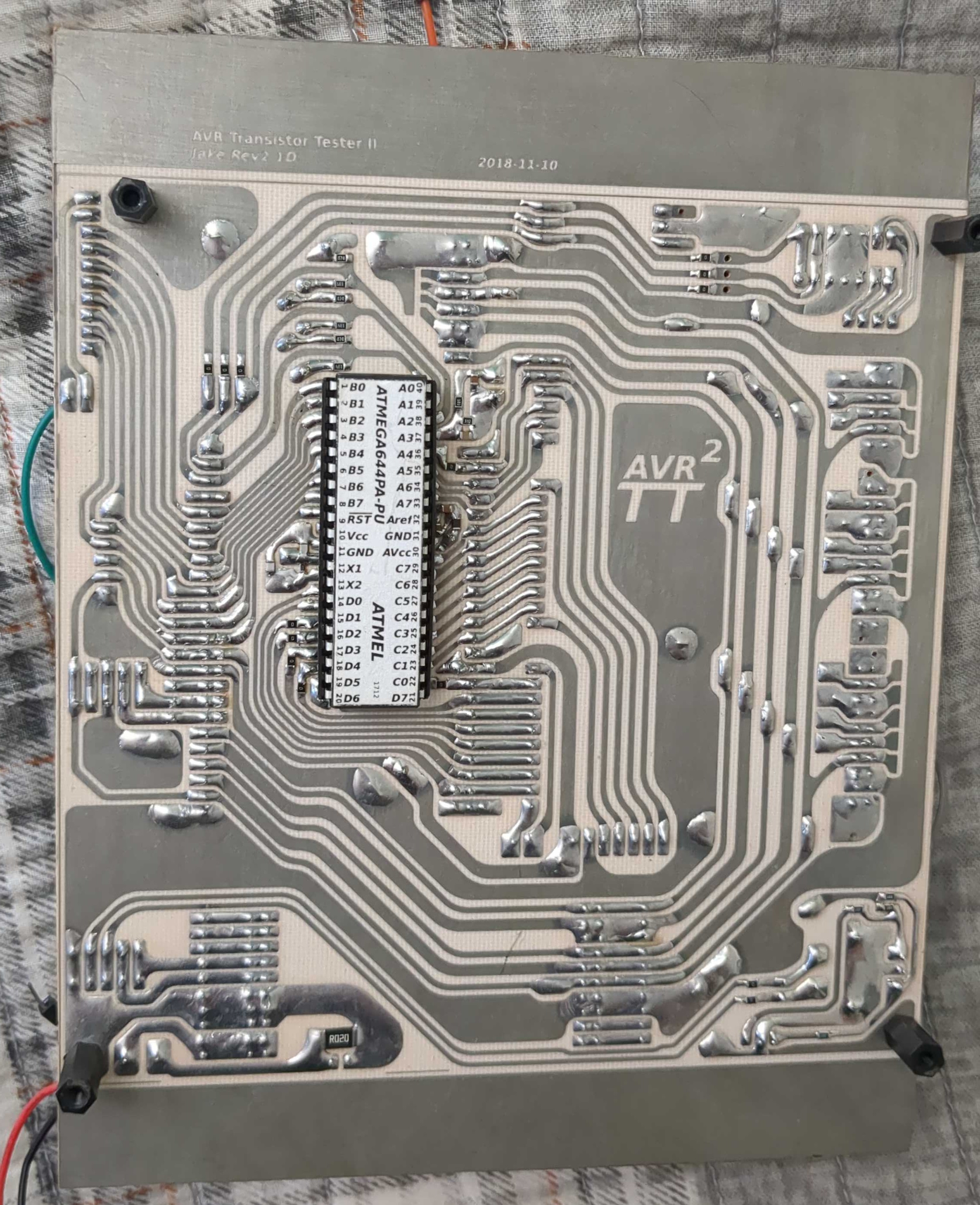

I was working on integrating my thrift store junk iPod radio into my laptop bedstand side table when I realized I had never taken apart this old junky Logitech computer speaker set someone threw away. It sounds terrible because the monitor speakers are large tweeters. They are good tweeters, but terrible as a primary driver. After taking apart the little woofer that came with them, I got the little three channel amp pictured. The iPod clock radio I'm using in my bedside stand is just a two channel audio amp and I would like to have some better sound, and I might like to use these tweeters with a woofer. So I started making an enclosure design to 3d print for that amp to work in parallel and fit into my laptop stand to make a 5 channel setup with the flexibility to remove this 3 channel amp if I want to use it for anything else. I don't want a wire to my audio jack on my laptop so I want to have a Bluetooth option, and that is what lead me here.

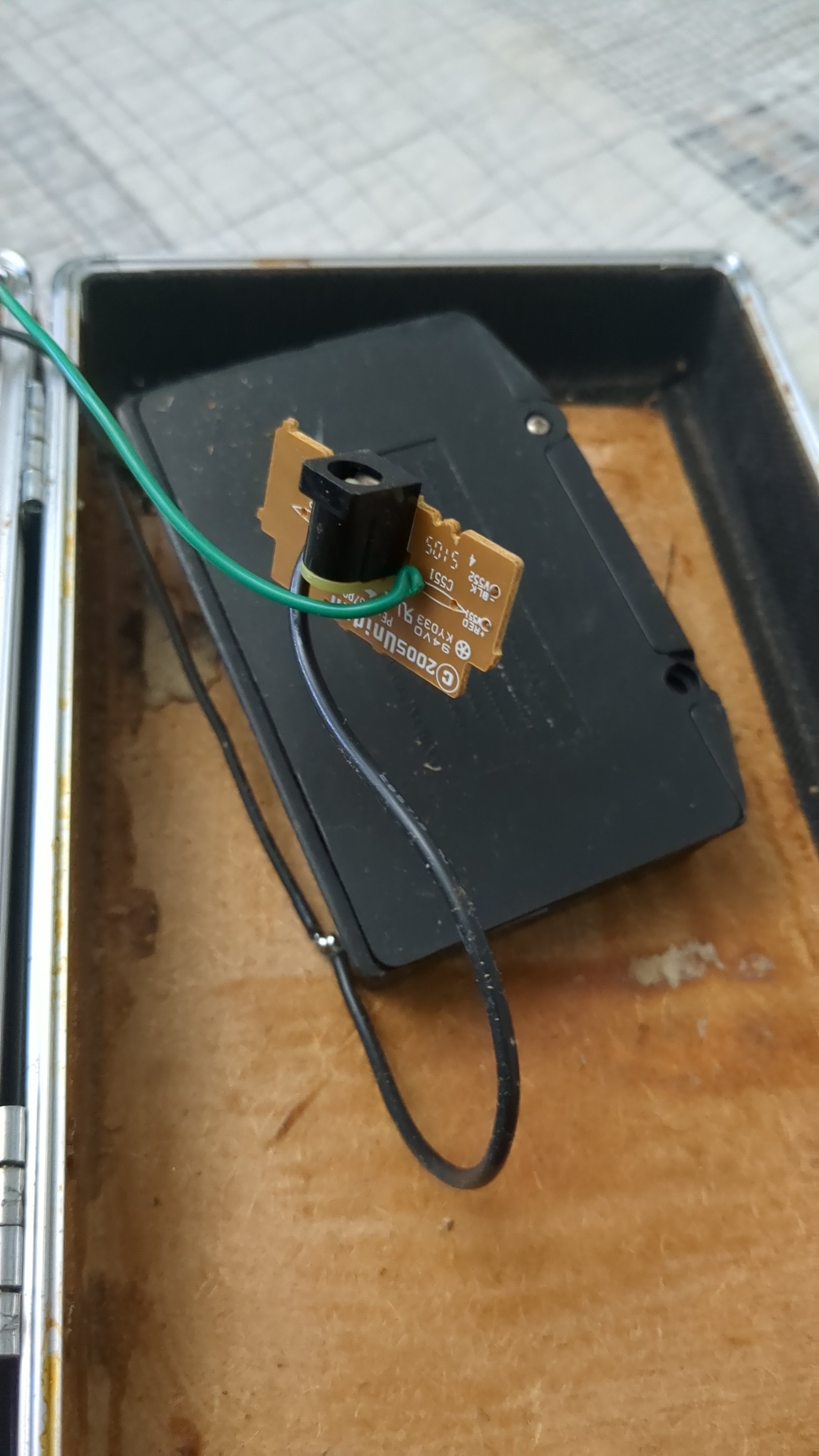

Actually, yesterday I started building with the other Bluetooth module pictured above. That was from some active noise cancelling headphones. Its wiring looks much more complicated because it had 3 mics. I was building an enclosure for it, but I think I would like to see how well it works in a more dedicated project. I wonder if the noise canceling can work in the open room. I think it might work in my little alcove space and with the way I am setting up my laptop stand.

I'm still planning on trying to make some cardboard pulped and pressed tiles of some sort for the GPU water cooler but I need a junk store blender first. As soon as I have the stereo amp figured out, I have all the other pieces modeled and just need to fit an enclosure around them... just... Life's about the journey not the destination.

Anyways, another post in the Lemmy be dead rn hours.